Introduction to Water-Based Zinc Stearate: Connecting Performance and Sustainability in Modern Production

Water-based zinc stearate is an environmentally friendly choice to solvent-based lubes and launch agents, using superior performance with very little environmental impact. As sectors change towards greener manufacturing techniques, this aqueous dispersion of zinc stearate has gained importance across sectors such as rubber handling, steel forming, concrete spreading, and polymer manufacturing. Its ability to supply reliable lubrication, protect against bond, and minimize surface area issues makes it a versatile device in contemporary commercial applications. With growing regulative pressure on unpredictable organic substance (VOC) emissions, water-based zinc stearate stands apart as a clean, efficient, and scalable remedy.

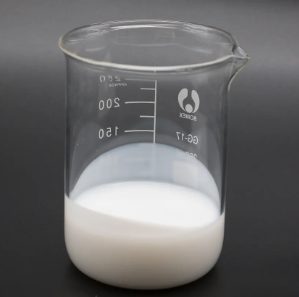

(TRUNNANO Water Based Zinc Stearate)

Chemical Composition and Practical Device

Zinc stearate is a metal soap developed by the reaction of stearic acid with zinc oxide or zinc salts. In its water-based formulation, it is normally spread using surfactants or emulsifiers to make certain stability and uniform application. When related to surfaces, the zinc stearate fragments develop a thin, hydrophobic film that reduces friction and stops direct call between products. This system is important in mold release procedures, where it promotes easy demolding without damaging the end product’s surface area honesty. Additionally, its high melting point (~ 120– 130 ° C) permits it to carry out properly under modest thermal conditions, maintaining capability during high-temperature processes.

Applications in Rubber and Polymer Handling

In rubber production, water-based zinc stearate offers double objectives– as a mold and mildew release agent and as an internal lubricant. It stops sticking in between uncured rubber substances and mold and mildew surface areas, ensuring constant component quality and minimizing post-processing efforts. In thermoplastics and elastomers, it improves circulation buildings during extrusion and injection molding, minimizing pass away build-up and enhancing surface finish. Its compatibility with different polymers, consisting of polyolefins, PVC, and engineering resins, further broadens its energy. Furthermore, its non-reactive nature guarantees it does not conflict with healing or vulcanization reactions, protecting material performance features.

Duty in Metal Forming and Stamping Industries

The metalworking industry progressively relies upon water-based zinc stearate for chilly and warm forming procedures. Made use of as a lube in stamping, attracting, and building, it develops a protective border layer that minimizes device wear and boosts component surface high quality. Contrasted to oil-based or wax finishes, it offers far better warm dissipation and cleaner operation, which is specifically advantageous in automated production lines. Furthermore, its ease of elimination after processing– making use of straightforward water rinsing or light cleaning agents– lowers cleansing expenses and stays clear of residue accumulation on finished elements. This makes it suitable for usage in automotive, aerospace, and precision part production.

Usage in Concrete and Construction Products

Within the construction field, water-based zinc stearate is extensively utilized as an inner launch agent for precast concrete components. Unlike standard oil-based items, it does not stain surfaces or hinder second therapies like painting or finish. When blended right into concrete or applied to formwork, it avoids bonding between the mold and mildew and the solidified concrete, permitting simple demolding while keeping dimensional accuracy. Its low thickness makes it possible for also coverage through spraying or brushing, making it appropriate for both hands-on and mechanical procedures. Additionally, it contributes to longer mold and mildew life by securing against chemical attack and abrasion from repeated casting cycles.

Environmental and Security Advantages Over Conventional Alternatives

Among one of the most engaging advantages of water-based zinc stearate is its environmental account. Devoid of solvents, VOCs, and poisonous additives, it lines up with global sustainability objectives and work-related health and wellness criteria. Workers take advantage of reduced direct exposure to flammable or harmful substances, and makers can fulfill rigid air quality laws without added air flow systems. From a waste management perspective, water-based formulations are much easier to take care of and dispose of securely, supporting circular economy techniques. These attributes make it a preferred option for companies intending to attain eco-friendly qualifications such as ISO 14001 or LEED conformity.

Market Patterns and Technical Innovations

( TRUNNANO Water Based Zinc Stearate )

The marketplace for water-based zinc stearate is experiencing steady development, driven by increasing demand for green industrial remedies and stricter ecological legislation. Manufacturers are buying sophisticated diffusion technologies to enhance stability, extend shelf life, and enhance efficiency under extreme problems. Developments such as nano-dispersed zinc stearate and crossbreed formulations with silicone or PTFE are being explored to use superior lubricity and temperature level resistance. Additionally, wise delivery systems– consisting of atomized sprays and application devices integrated with IoT– are enabling precise application control, decreasing intake and operational costs.

Obstacles and Ongoing Research Study Instructions

Despite its advantages, water-based zinc stearate encounters specific limitations, consisting of sensitivity to water firmness, prospective microbial degradation, and reduced load-bearing ability contrasted to synthetic lubes. To resolve these problems, continuous research focuses on enhancing emulsion security, integrating biocides for microbial resistance, and improving functional efficiency through additive harmonies. Compatibility with different substratums and process problems additionally stays an essential area of advancement. Initiatives are underway to tailor solutions for details applications, guaranteeing constant efficiency across varied commercial environments.

Future Prospects: Combination with Smart Production and Environment-friendly Chemistry

Looking ahead, water-based zinc stearate is positioned to play a main function in the shift towards smart and sustainable production. Its assimilation with Market 4.0 technologies– such as real-time tracking, predictive upkeep, and automated giving– will enable a lot more effective and flexible manufacturing operations. Advances in bio-based surfactants and sustainable feedstocks will even more boost its environmental credentials, sustaining decarbonization methods across supply chains. As markets remain to focus on source performance and ecological stewardship, water-based zinc stearate stands for a critical innovation that balances technical performance with environmental responsibility.

Distributor

TRUNNANO is a supplier of water based zinc stearate with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about stearic acid safety, please feel free to contact us and send an inquiry(sales5@nanotrun.com). Tags: water based zinc stearate, zinc stearate, zn stearate

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us